Save 2 Work Days on a Penstock Inspection with the ASIO X Drone

Case Study on the Utilization of Drones for Confined Space Inspections

in the Hydropower Industry

Flight time

12 minutes -

1 battery

Drone

ASIO X

A minimum of

2 work days

saved

Hydropower

Industry

Introduction

Inspecting and maintaining infrastructure, such as penstocks and tunnels, is crucial for hydropower facilities, where efficiency, safety, and reliability are essential.

However, due to their design, these structures present unique inspection challenges, mainly because of their steep inclination, slippery interior surface, and limited access points.

To address these challenges, Groupe E, the largest energy company in Western Switzerland, engaged Flybotix to conduct a few remote inspections using the ASIO X drone.

Background and Objectives

After a severe storm damaged the terrain in the vicinity of a penstock in the Swiss Alps, Groupe E, a major hydropower plant operator, needed to inspect the interior of the penstock for potential damage.

Given the penstock’s small diameter of 1.2 meters and steep inclination of over 30°, traditional inspection methods posed significant safety risks and challenges for human workers.

The primary goals were clear:

- Streamline the Inspection Workflow: Use drone technology to conduct a visual inspection, minimizing personnel involvement.

- Enhance Data Quality: Collect high-resolution images and data for detailed analysis reporting.

- Improve Safety and Efficiency: Protect workers by eliminating the need to enter hazardous, hard-to-reach environments and reduce operational downtime.

Challenges

Accessibility

The narrow manhole (DN450) to access the penstock was partly obstructed by a high-voltage electrical cable.

Additionally, because of the limited access points within the penstock, the area of interest would require climbing or descending more than 170 meters before beginning the inspection.

Safety Risks

The potential lack of oxygen, limited space for movement, falling hazards, and material or personnel safety.

Lighting Capabilities

The inspection required locating eventual defects in the protective coating, necessitating detailed visual clarity within a confined and dark space.

How is the penstock traditionally inspected?

Manhole access point for this inspection

Traditionally, the materials needed for such an inspection include a special sleigh and long-length ropes, which allow highly trained personnel to move inside the asset and carry potential equipment, including powerful lighting.

In addition, for each individual inside, two additional people are required to help with movement inside the asset: one must be there for security and one for coordination (typically an inspector).

Furthermore, preparing for this type of mission takes two days and involves a team of three people. This includes complex logistics, preparation of the area of interest, assessment of the direct environment, and establishing a safety and health at work plan (PSST) required when entering confined spaces.

On the day of the inspection, five people are mobilized. In general, the inspector is not the same person as the confined space entry workers, requiring multiple back-and-forth in the confined space to ensure sufficient and accurate data (pictures of points of interest) is acquired, as the inspector does not get real-time information.

The Asio Solution

To tackle these challenges, Flybotix delivered a comprehensive solution encompassing data collection, streamlined data management, and a cloud-based collaborative platform.

ASIO X Drone

- 4K camera

- In-flight assistances such as Tube Lock and Height Lock

- 20 minutes of flight-time

- Multi-gas sensor module

- 40’000 lumen of on-board lighting capability

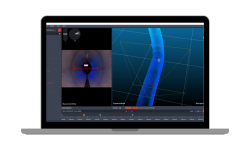

ASIO Explore

Desktop app for edge data processing.

- Precise measurements of defects and distances

- POIs identification

- Point Cloud manipulation

- Real temperature monitoring

- Report generation

ASIO Connect

A Cloud-based platform for intelligent asset management.

- Collaborative and scalable

- Role-based access control

- Data management

- Digital twin management

- API integration

Inspection Workflow with ASIO X Drone

Preparation Phase

Before the flight, a thorough pre-flight briefing was conducted with the client through e-mails and a call.

Key considerations include:

- Reviewing the penstock blueprints to understand its layout and specific requirements.

- Identifying entry and exit points for the inspection area, while noting any potential obstacles.

- Planning for drone retrieval in the event of an issue or malfunction.

- Assessing environmental materials that could impact signal strength during the inspection.

Overall, this preparation, which typically takes 1–2 hours, ensures that all parameters are optimized for a safe, efficient, and highly accurate inspection process.

Execution Phase

The ASIO X drone was carefully deployed within the penstock. However, due to the obstruction caused by a high-voltage electrical cable, the drone had to be manually placed sideways inside the manhole.

From the drone inspection perspective, flying in such tubes presents challenges due to the aerodynamic turbulence generated during flight.

Fortunately, with Tube Lock assisting the pilot, the drone’s lateral position in the tube is kept centered effortlessly. By combining this with the Height Lock functionalities (Ground and Roof Locks), the drone maintains a constant height from the tube’s floor and roof sections despite the steep inclination angle.

As a result, this leaves only one degree of freedom for the pilot to control. Specifically, by controlling the drone’s pitch angle, the pilot defines the flight speed while remaining automatically centered within the penstock. The pilot steadily moves forward, ensuring a thorough and stable inspection.

Given that the inspection area is situated 170 meters from the nearest manhole, a long flight time was necessary to ensure that the inspection could be carried out thoroughly without rushing through the area of interest before heading back.

The ASIO X’s extended flight time enabled a comprehensive visual assessment without the need to withdraw and swap batteries.

In addition, during its flight, the ASIO X drone captured detailed visuals and located a series of defects in the protective coating. The screen sharing feature provided the inspector with a real-time view of the inspected area.

At the end of the inspection, a review of the footage and validation from the client completed the mission.

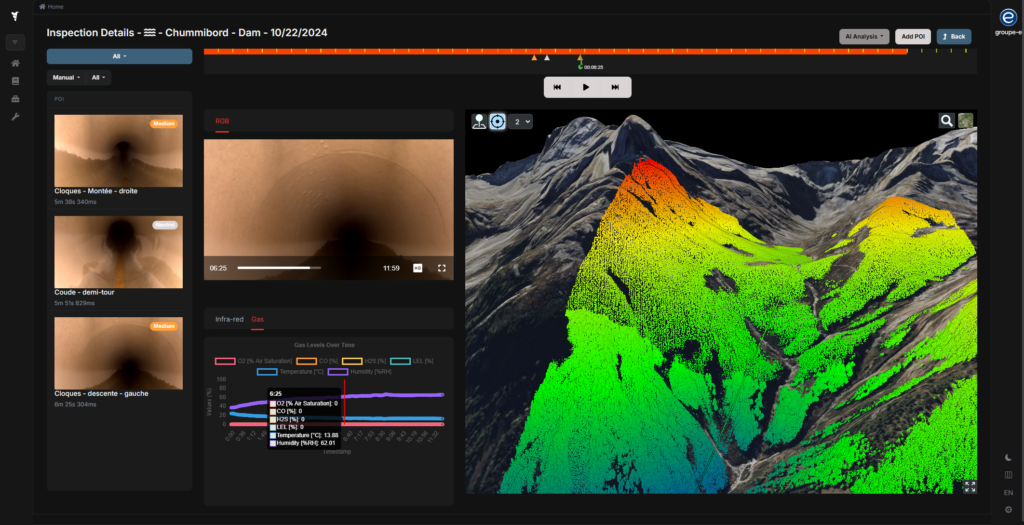

Data Analysis and Reporting

From Data to Decision-Making

The collected data is not just raw information — it’s transformed into actionable insights.

The client received a detailed report complete with high-resolution images and data. These insights support proactive maintenance, help prioritize repairs, and ensure compliance with safety and operational standards, all while reducing downtime and inspection costs.

ASIO Connect multi-video support and 3D visualization system

Results and Impact

ASIO X Cut 2 Days of Work in Industrial Operations

In just 12 minutes, the ASIO X accurately assessed the interior condition of the penstock and successfully identified any anomalies in the coating.

Taking into account the pre-mission preparation discussions, internal meetings, and the on-site briefing, the total time for three people did not exceed half a day (excluding travel). This is more than two days faster than the traditional inspection method, which typically requires over 10 man-days.

This results in thousands of dollars in labor savings, improvements in operational uptime, and unparalleled enhancements in worker safety. Additionally, it protects customers’ reputations by minimizing the risk of accidents related to inspection errors.

“The conclusion for the time savings alone is over two days, along with unequivocal inspection feedback regarding the images, as the video can be viewed and reviewed“, said Stéphane Dupont, Groupe E.

View More Case Studies

Energy production

Discover How Flybotix’s ASIO Drone Reduced Inspection Time, Enhanced Safety, and Saved 60% on Costs for Leading Energy Provider Groupe-E.

Energy Production

Drone based inspection inside Oil Tanks allows 57% reduction in inspection time and saves days of asset uptime.

Mining

Enhance Safety and Efficiency in Roof and Mill Inspections at Baramin with Flybotix ASIO Drone.

Energy Production

How an Engineering Firm Halved Inspection Time, Saved 50% on Costs, and Improved Safety Using Flybotix's Advanced Technology

ELEVATE YOUR INSPECTION PROCESS

Talk to Our Team

Connect with our team for a firsthand look at the drone’s stability, assist functions, and maneuverability, ensuring all your questions are answered to experience our advanced technology.